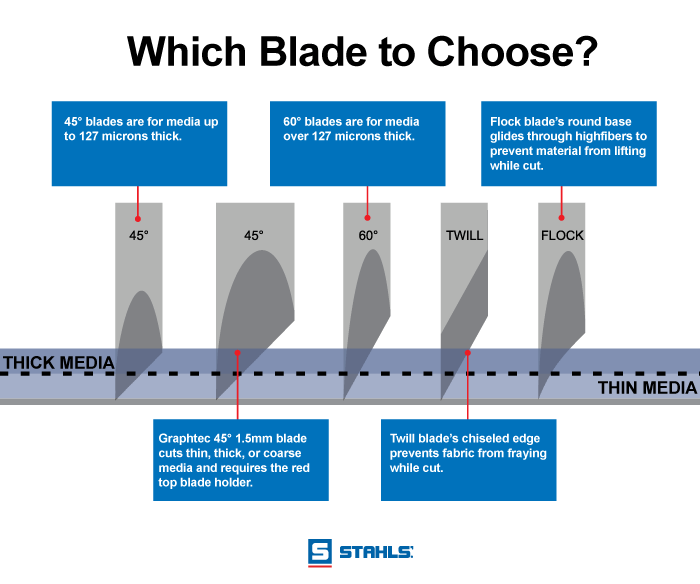

Based on Cut thickness,backing sheet etc.Blades are hard and brittle so.

its easier to use masking tape for vinyl transferring and weeding.Make sure the adhesive is less sticky(use your body to remove glue)

Objectives

Individual Assignment

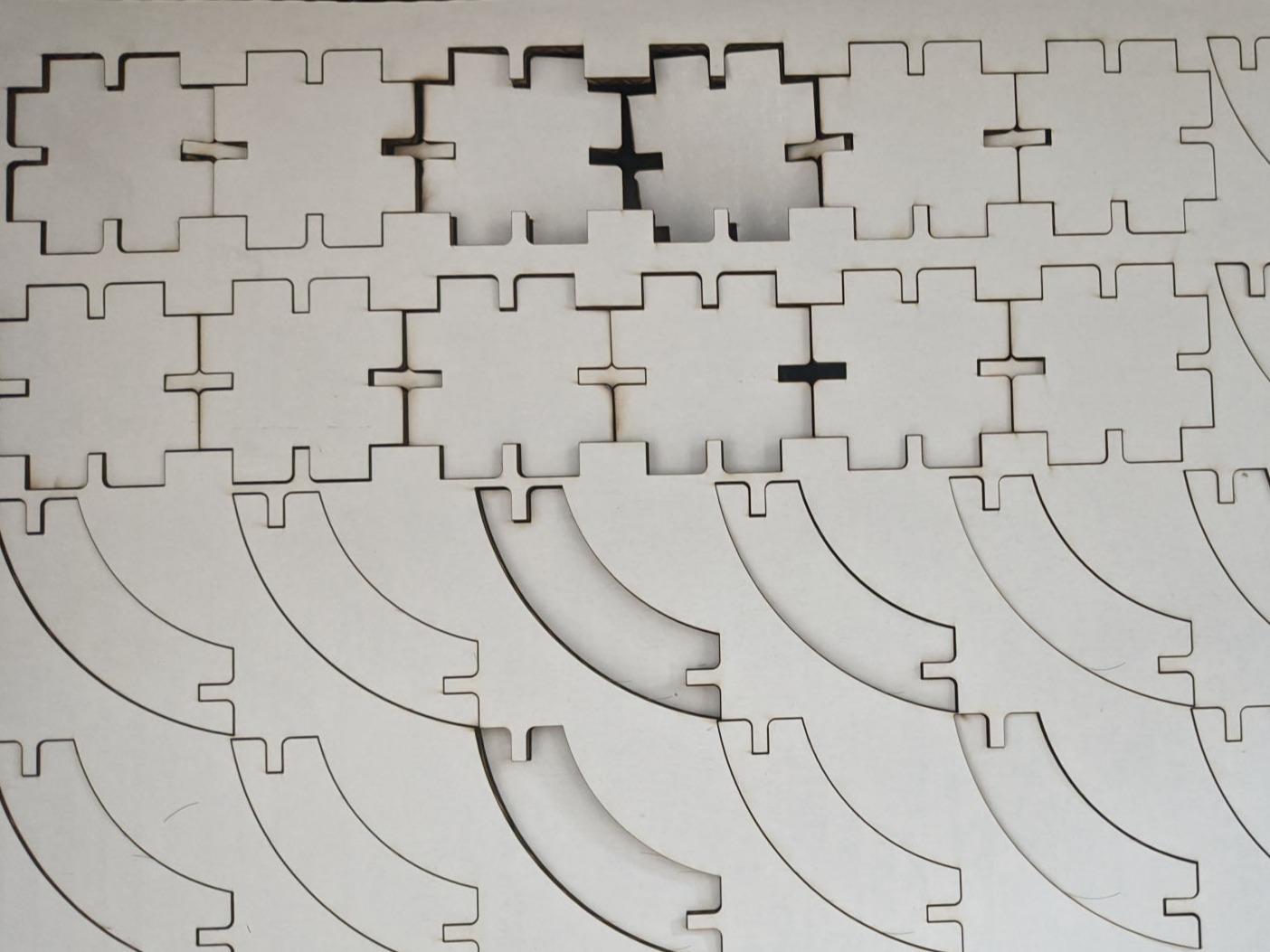

1) Design, laser cut, and document a parametric press-fit construction kit, which can be assembled in multiple ways. Account for the laser-cutter kerf.

2) Cut something on the vinyl-cutter

Group Assignment

1) Characterize the laser cutter's focus, power, speed, rate, kerf, and joint clearance.

2)Document the work.

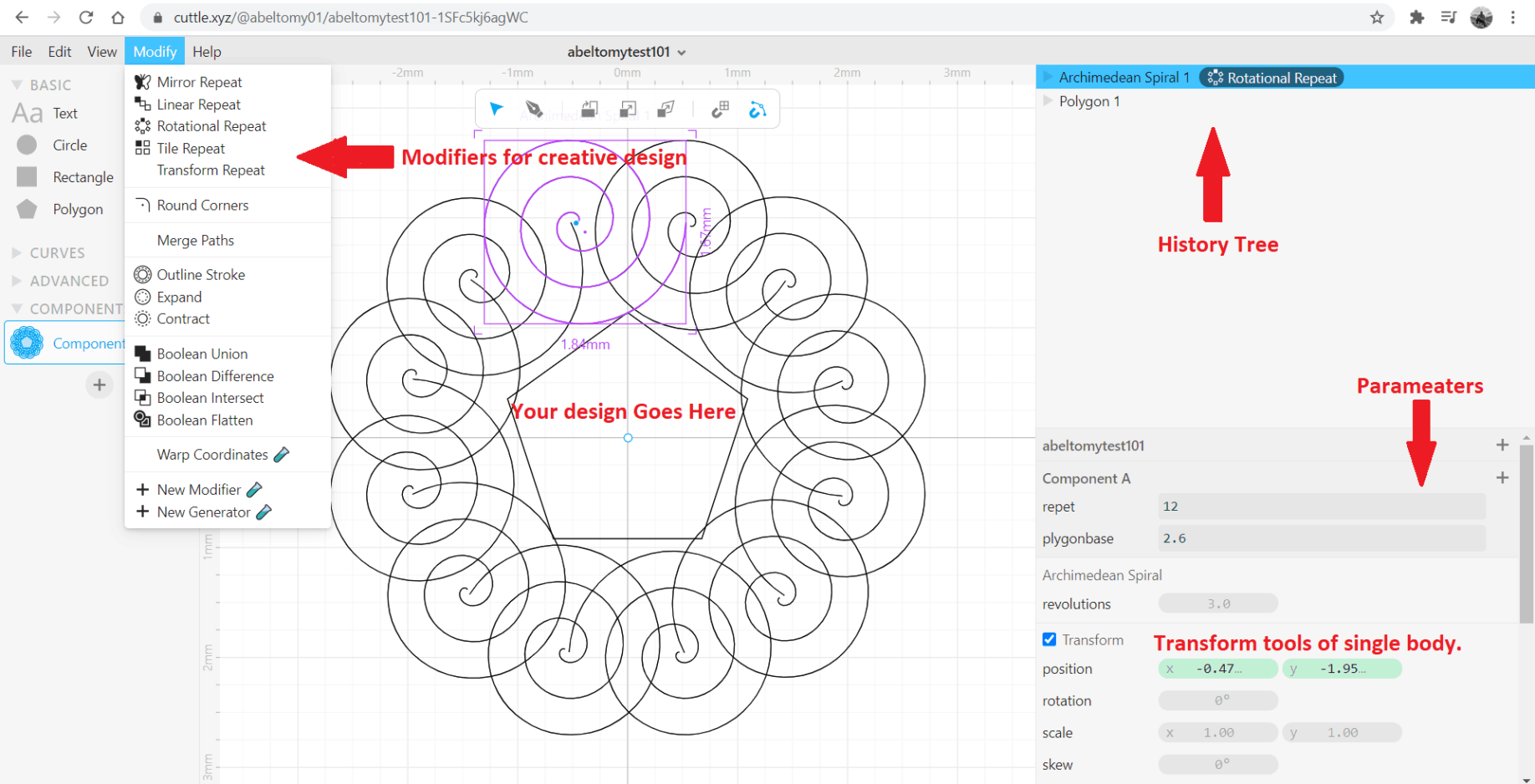

Know The Possibility's. In CAD & CAM

1. Inkscape Extensions .

2. Flatfab - Fabrication Design Software.

3. Deepnest-Open source nesting software.

4. Grasshopper-Graphical algorithm editor tightly integrated with Rhino’s 3-D modeling tools.

5. FabMods.

6. Create your own QR code.

Caster causes a tool to align with the direction of travel, and can be accomplished either by caster displacement or caster angle. Caster displacement moves the steering axis ahead of the axis of wheel rotation, as with the front wheels of a shopping cart. Caster angle moves the steering axis from vertical.The tool is just attached to a ball bearing it it works like charm automatically.

Based on Cut thickness,backing sheet etc.Blades are hard and brittle so.

its easier to use masking tape for vinyl transferring and weeding.Make sure the adhesive is less sticky(use your body to remove glue)

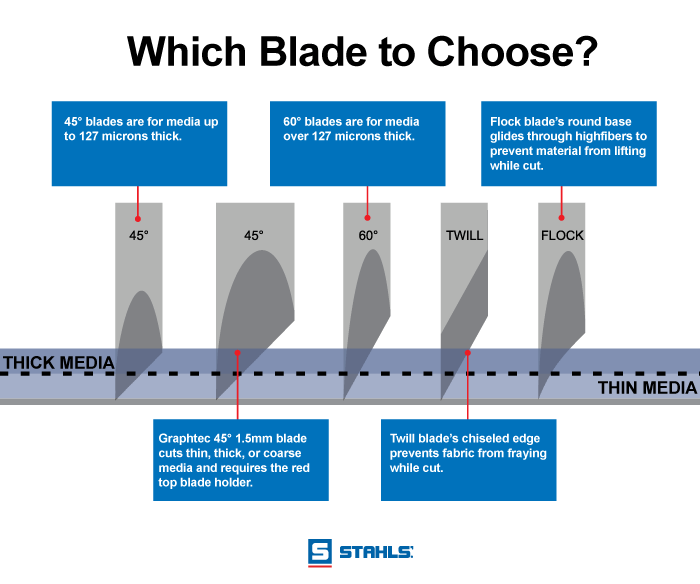

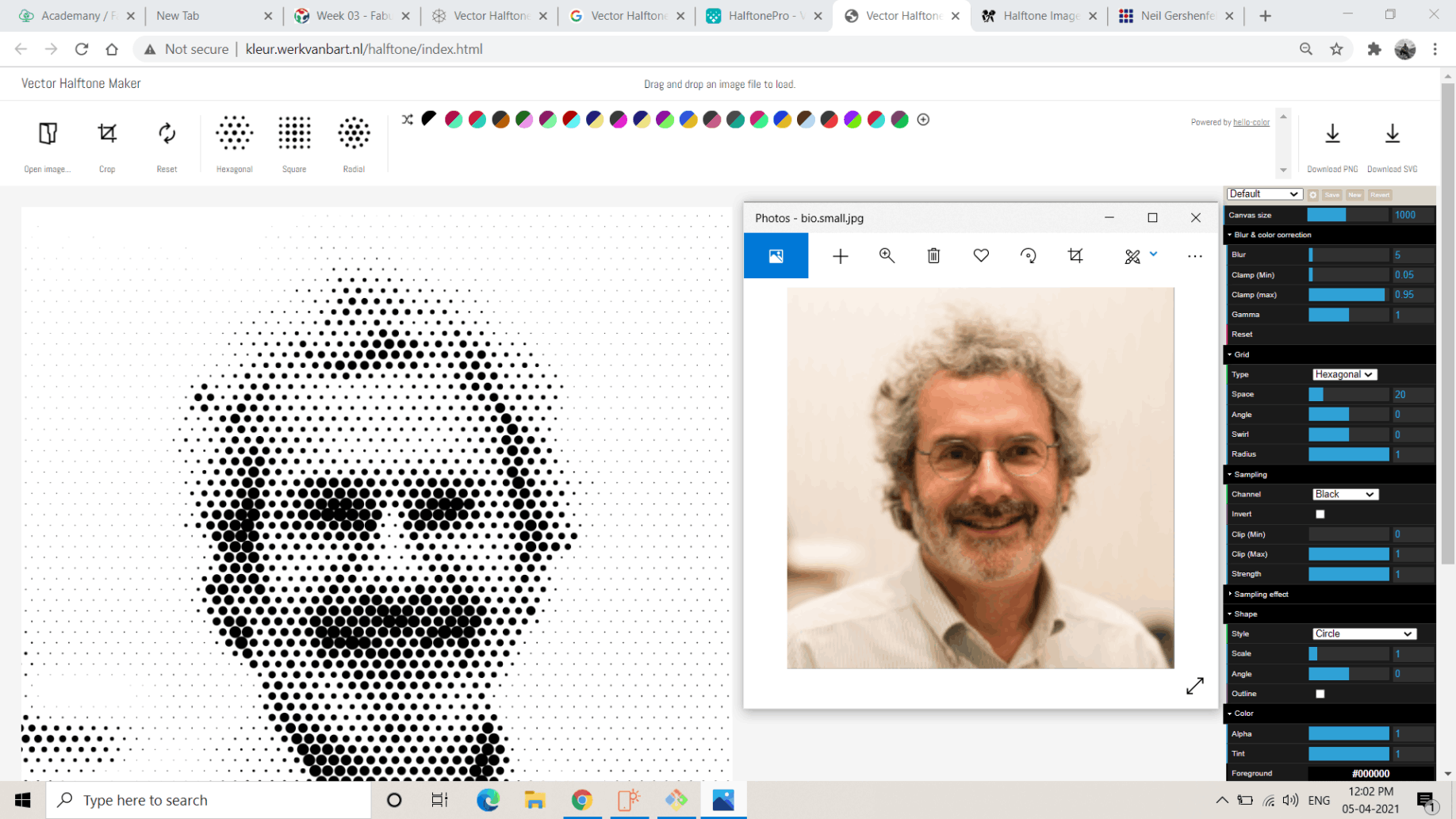

Inkscape a open source tool is used for creating the design that to be fed into the machine.Firstly I planed to make make batman logo then,I decided to make a fab lab logo for a circular light in the fab lab so that it loos so cool.i am inspired from batman movie where batman logo projected by a light source.Raster to Vector(Trace Bitmap.)

So i measured the LED light dimensions in Our lab and its found to be with a diameter with 19.5 cm,Then i created vector image by bit mapping a Fab Lab logo within the constrains of measurements done by document setting adjusting the canvas to 20 cm*20 cm.

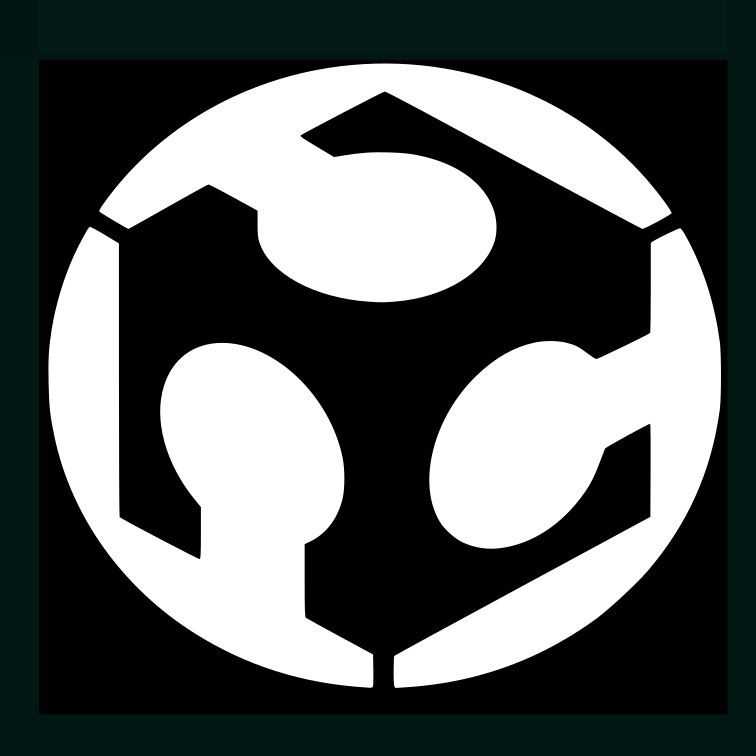

Since the cutting parameters change with materials ,the environment etc the cutter needed to be calibrated and find optimal value for force(Over/Under Cut and speed (problems including shearing,frictionlocks) for the specific time and condition.A test is done like in image on right so that if the cut is perfect we can take out the circular one without effecting inner square.

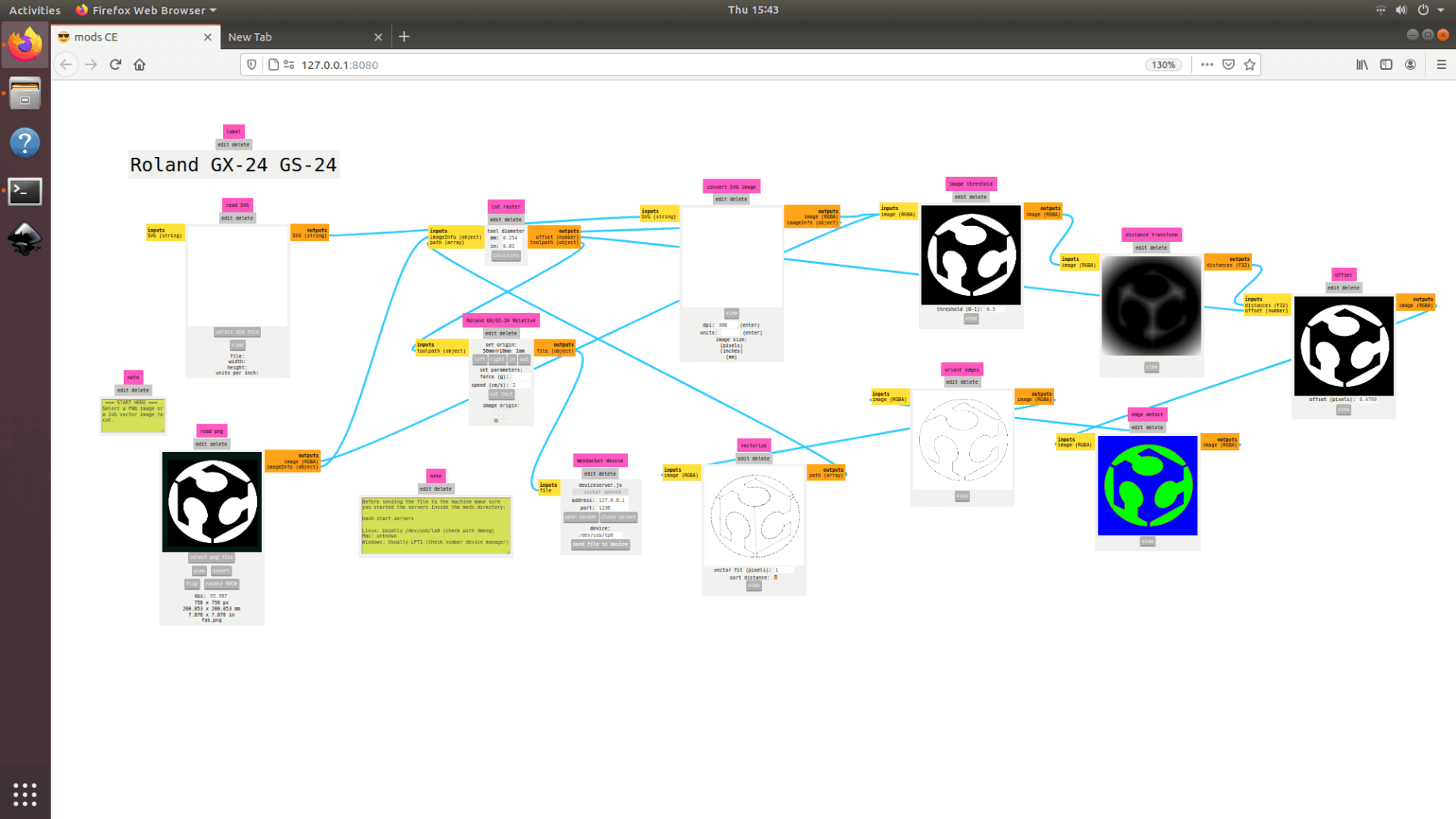

Even tho there are propitiatory software's for the cutter,our lab use Fab mods due to its flexibility and adaptability.And you can update and edit in browser itself,I found it very useful.Mods could potentially be used for CAD, CAM, machine control, automation, building UI, read input devices, react to to physical models, and much more.Steps Involved in Opening Mods

.Png loaded and tool-path is generated.

From the system,mods send the data(it includes force,speed,how the motors-drivers need to move etc) and its interpreted to machine language and the cut starts.weed it use it.

Me Fixing the vinyl.

So Cool,right?

2.Test Cut (calibrating force and speed)and Cutting.

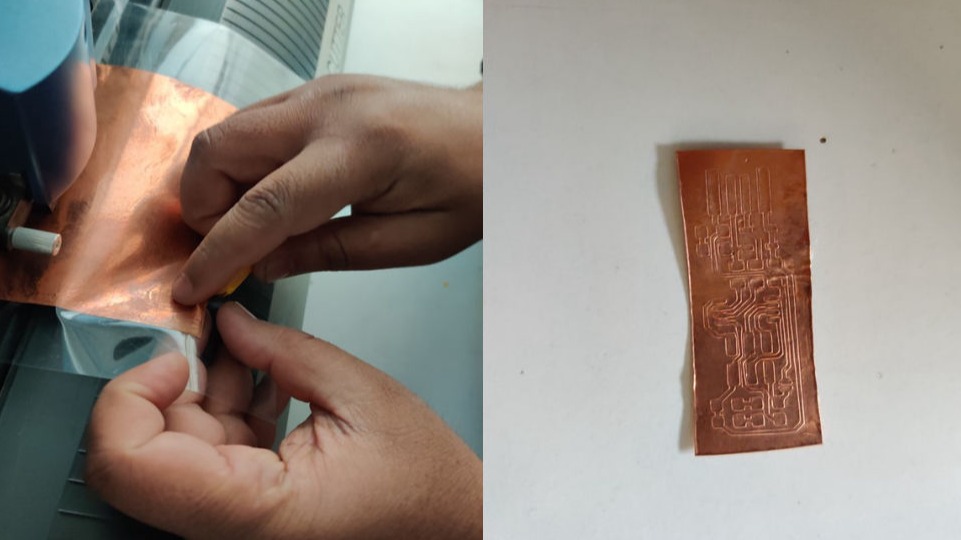

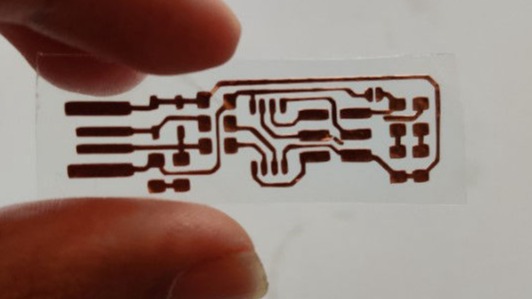

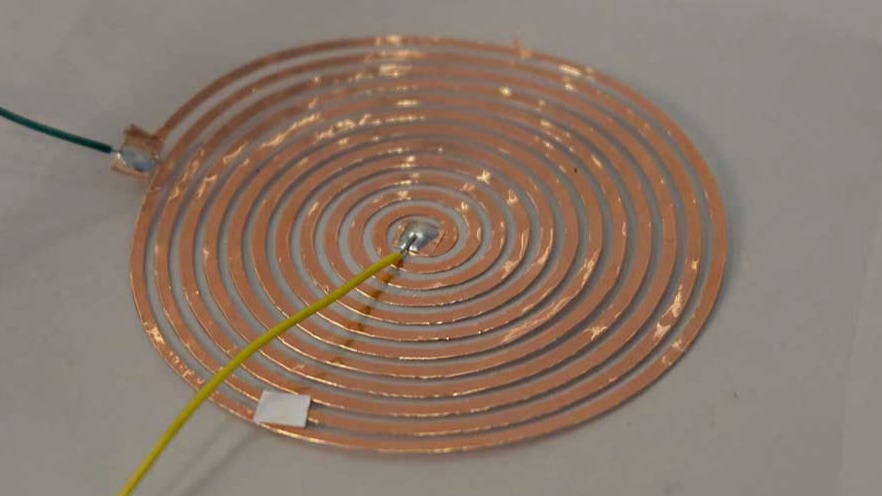

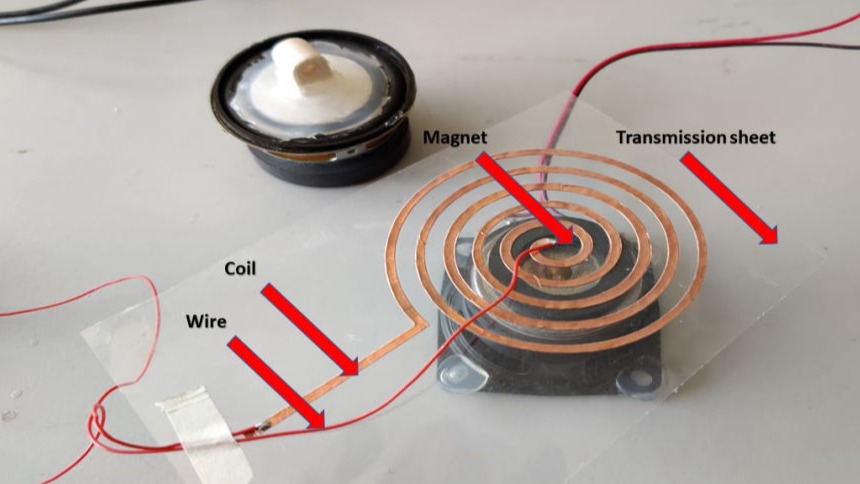

1.Sticking copper sheet to transmission/backing sheet.

Flexible FabTiny ISP.

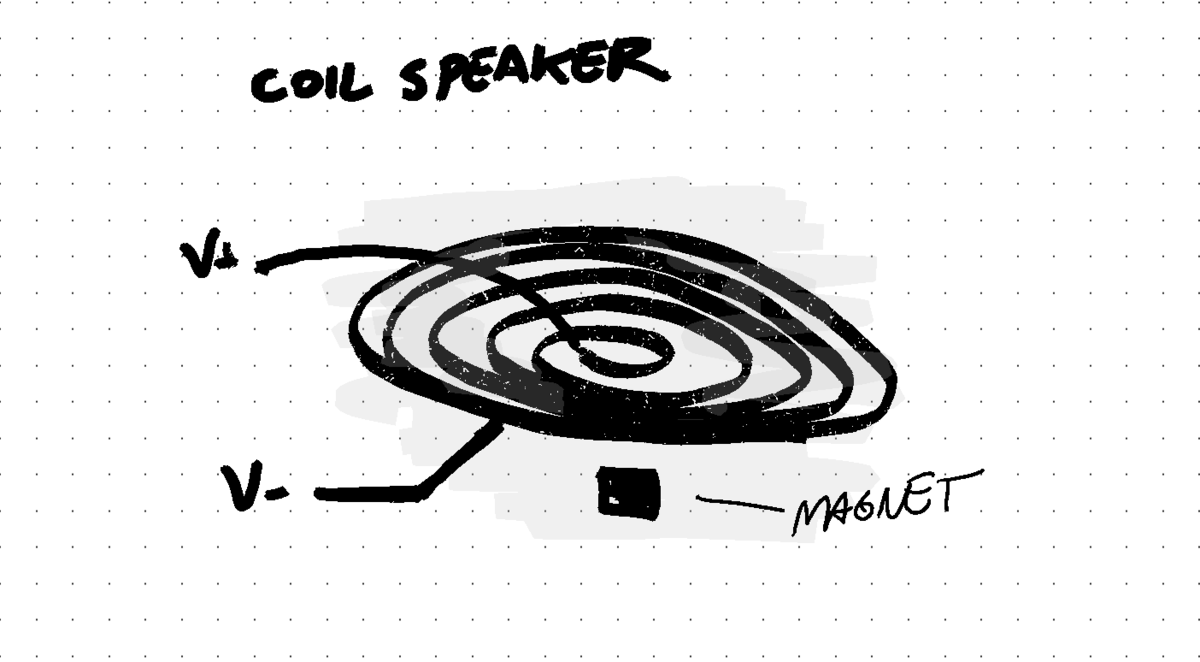

Working Principle.

Test 102. Increased turns and decreased distance between consecutive coils.

Test 101.

For testing we had connected the coil to a CRO with a magnet under the sheet to test the speaker.Use headphones for better experience.Frequency is changed to get a notifiable change.

Other this to try ?

Thermal transfer of Vinyl using Iron Box.

Sandblasting Mask

Screen Printing

Laser power, P

They can be set as a percentage between 0 and 100%. 100% is maximum power. For dark wood engravings or stamp engravings, you generally need high power, whereas low values are used for materials such as paper.

Cutting Speed, v

The Speed laser parameter describes the movement of the laser head. Fast speeds lead to short exposure times, slow speeds lead to long exposure times. For example, large-scale engravings of TroLase materials are engraved at high speeds between 80 and 100%, but for photo engravings with lots of detail on wood, the speed should not exceed 10%. This setting also affects the quality of the laser cut.

Number of Passes N

The Pass parameter determines the number of engraving or cutting passes. With some materials, for example, it can be advantageous to engrave with lower power and high speed, and then repeat this process several times. This means that the material is less stressed per pass. For example, this approach is appropriate for a relief engraving.

Pulse frequency

As with the laser power, the pulse frequency can be matched to the relevant machining task. For example, it is recommended small contours are cut with reduced pulse frequency. The pulse frequency is also reduced when piercing in the ramp mode.

kerf

The laser burns away a portion of material when it cuts through(tool thickness). This is known as the laser kerf. More info click here.

Things to be careful using a Laser Cutter.

1.Machine must not be left unattended while it is operating (supervised operation).

2.Stop this machine immediately in case of failure or fire.(fire extinguisher in case of emergency).

3.Never Cut Material with Unknown Properties(reflective glass,PVC etc).

4.Fumes and Ventilation-Always on the carbon filter and never inhale the hazardous gas(especially acrylic..its carcinogenic) from the cutting operation.

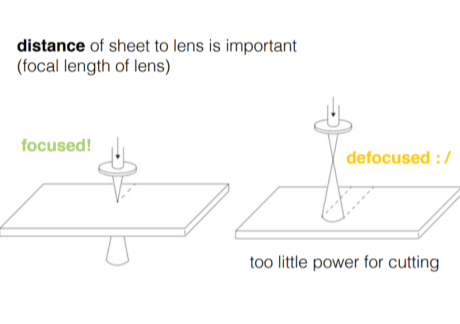

5. Every-time you change the material you need to refocus the laser beam so that this point is on the surface of the material.

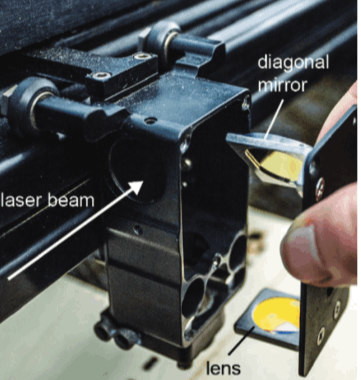

Ultimately, it’s a matter of focus. The laser is at its most powerful when its energy is concentrated into the smallest dot possible. That means there’s a “sweet spot” in front of the lens where cutting and engraving will be the most efficient, touch probe is effective.

No, they are made with a different type of machine.

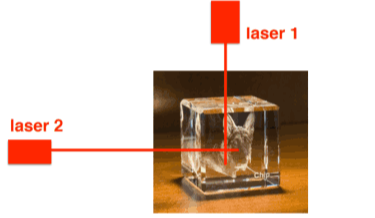

• two lasers from different sides aim at the same spot.

• where they interfere, the power is high enough to

break the glass and create a ‘dot’.

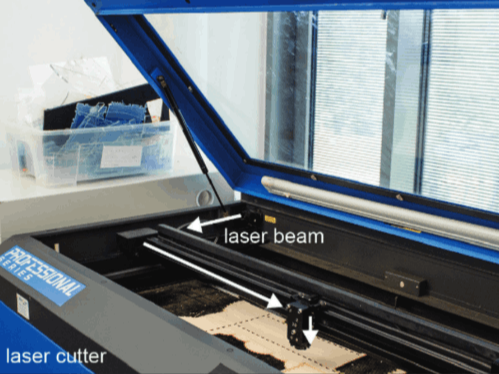

1. The very first step is to turn on the laser machine and the filter machine and the material is placed inside the laser cutter. It should be ensured that the material is properly placed.

2. The next step is to focus the laser. For this there is a focusing tool available with the machine. This is placed on a small groove in the Laser and the bed is raised using Z axis control button in machine panel until it touches the tool. The tools drops from the groove when the bed touches it indicating that the laser is now focused.

4.Move the effector to the desired location. This can be done by manually moving the effector in X & Y axis using machine control pad. Once this process is complete I can now start laser cutting. Yaay!

Air Filtration System And The Mighty Laser Cutter

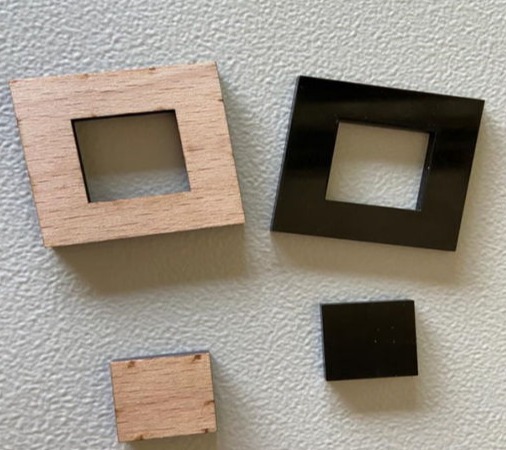

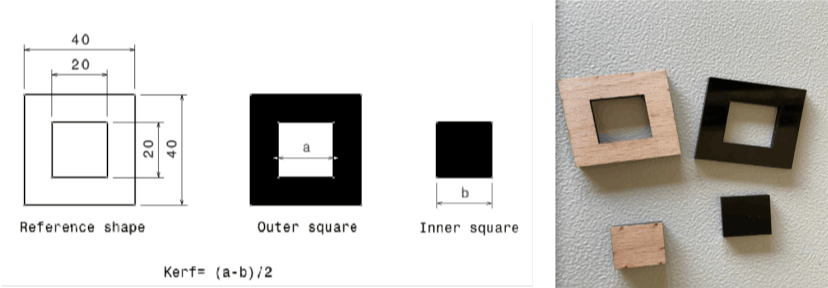

We tested on 4mm balsa wood and 4mm acrylic for the cutting parameters. A square cut of 20 x 20 mm inside a square cut of 40 x 40 mm was taken for the reference and following were the results.

1. For balsa wood 4mm,

Power=100

Speed=0.5cm/sec

Number of passes=1

frequency=1000

2. For acrylic 4mm,

Power=1000

Speed=1cm/sec

Number of passes=1

frequency=1000

The laser burns away a portion of material when it cuts through. This is known as the laser kerf and ranges from 0.08mm – 1mm depending on the material type and other conditional factors.

Kerf=subtracting inner dimension from the outer followed by dividing it by 2.

The kerf of 4mm wood is : 0.15mm

The kerf of 4mm acrylic is : 0.2mm

Joint clearance is the clearance between the mating parts two connecting bodies. There are three types of fits which care clearance, transition and interference fit. You can choose according to your requirement.Then keeping the standard thickness of 4 mm, jig with slots starting from 3.4mm to 4 mm with 0.1 increment is para-metrically designed and made with the same laser cutting setting used while making kerf jig.

The the fit was ok with 3.5mm slot but was rigid with 3.4mm slot which means if we want to keep a rigid fit, we need to keep overlap of 0.45 mm total and 0.225mm for one side. So the dimension of the hole should be (thickness-kerf-overlap=4-0.15-0.45 = 3.4mm). This will be used to design the parts.

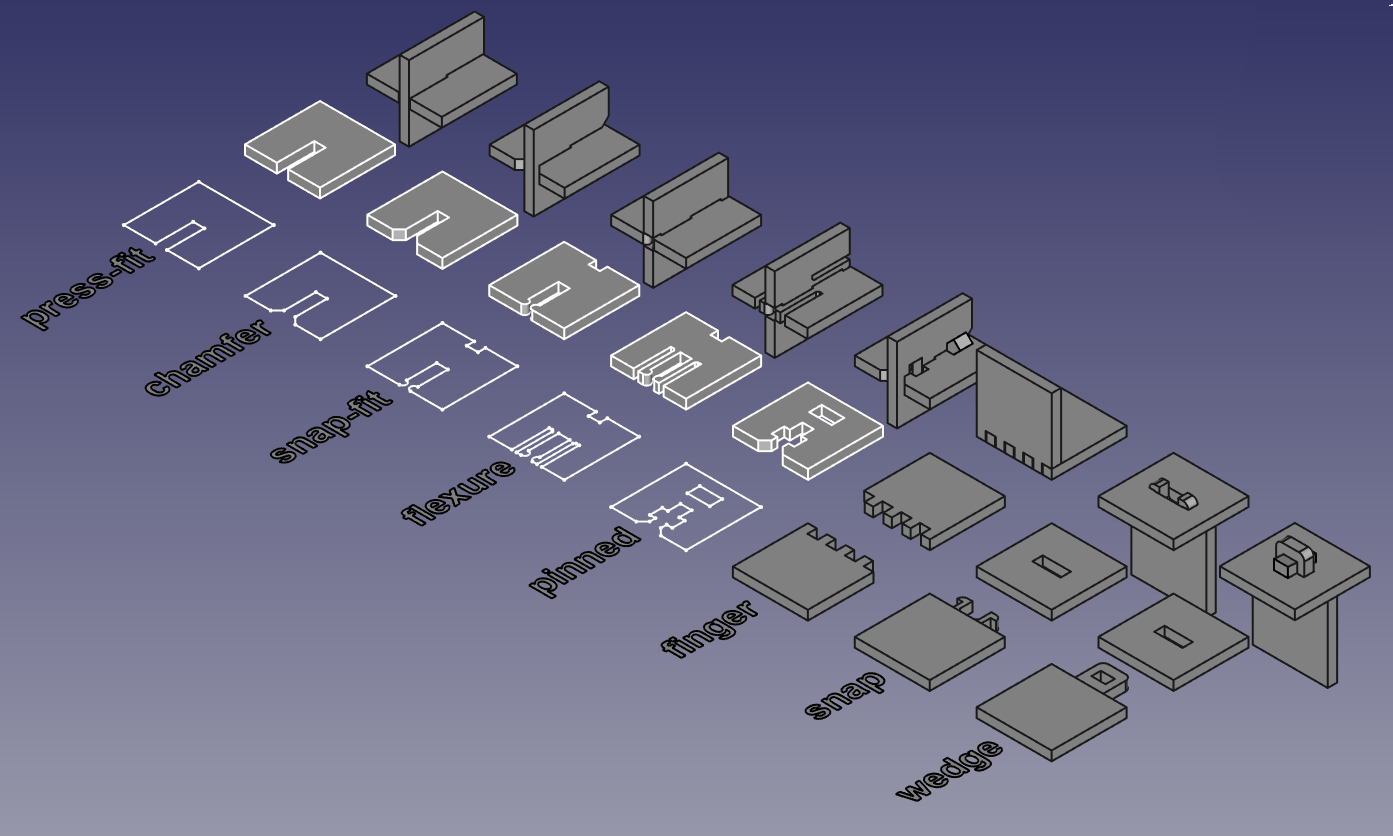

Different Types of joint.

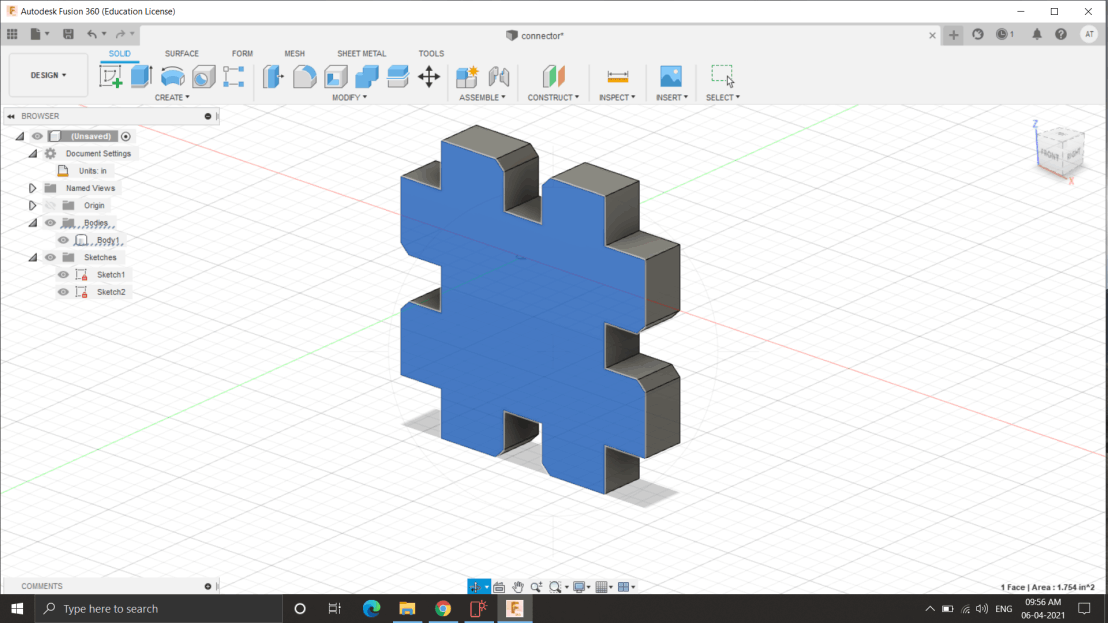

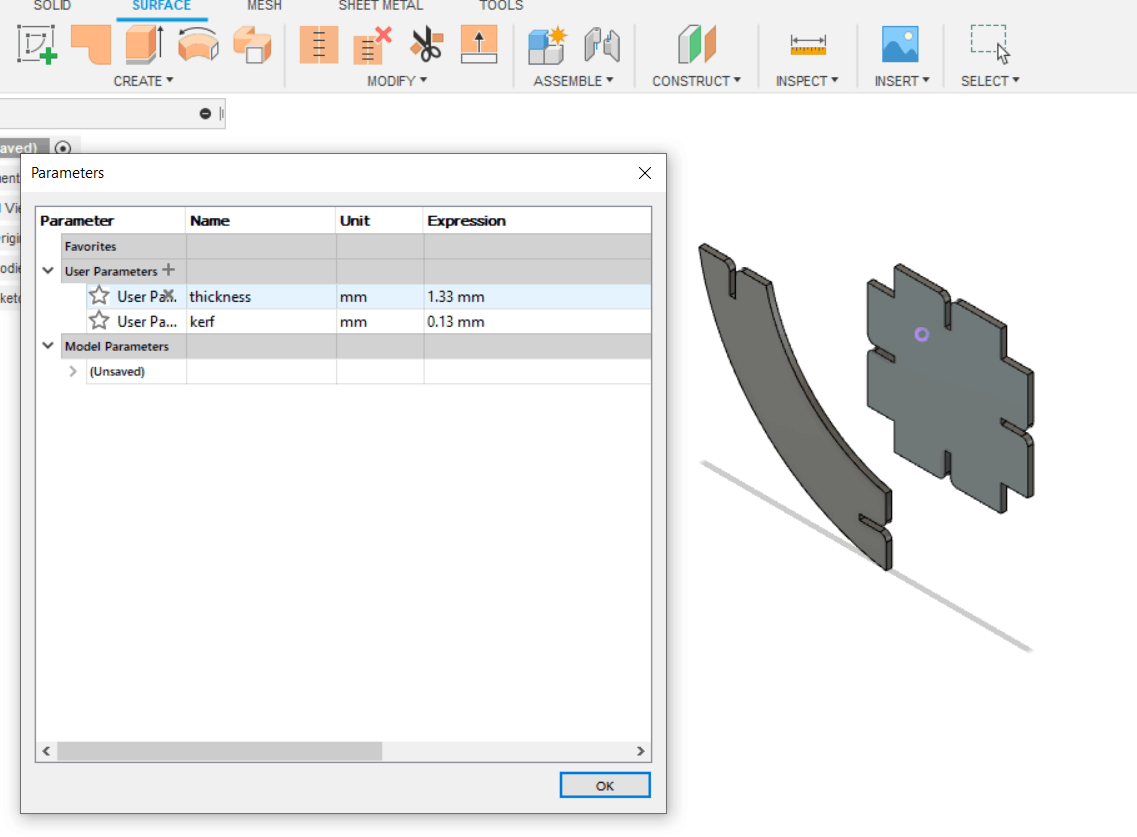

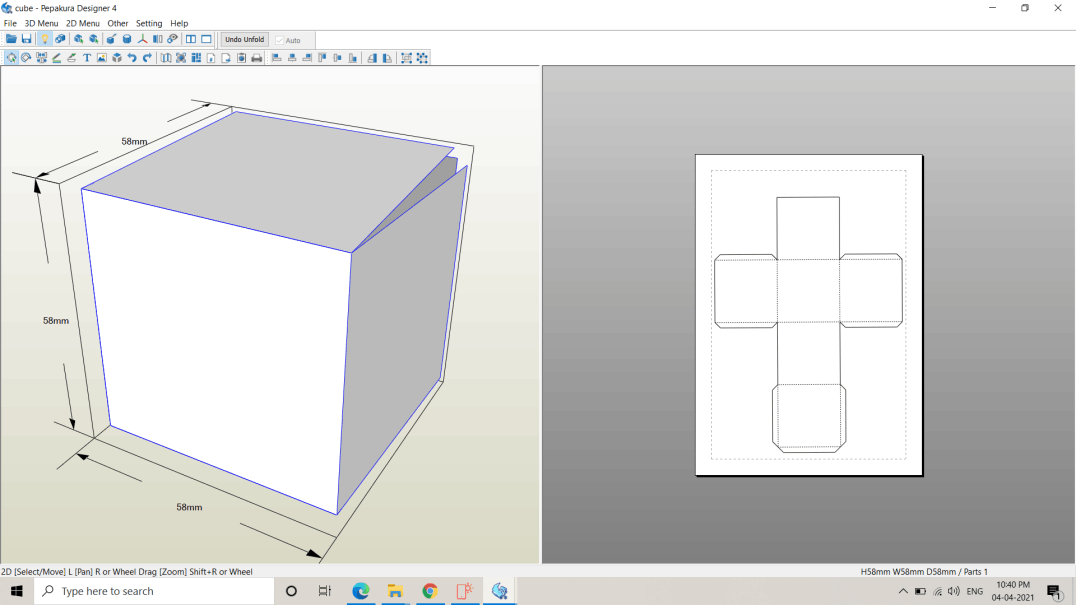

I added 2 user parameters as thickness and kerf in the design so that i can cut using different thickness sheet.You can add parameters in "modify" drop down.

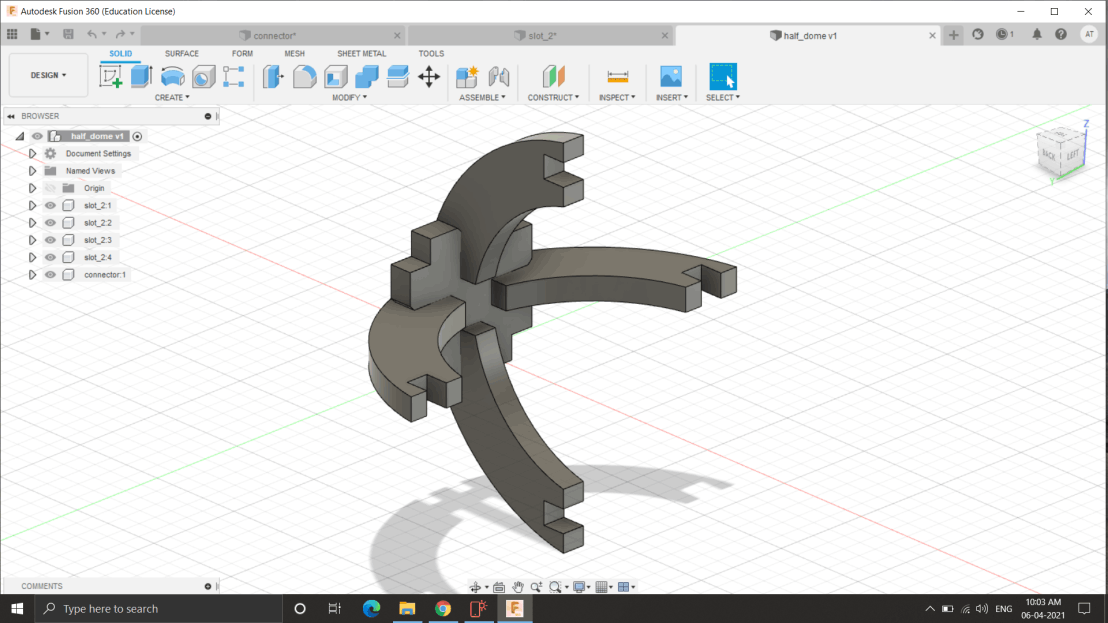

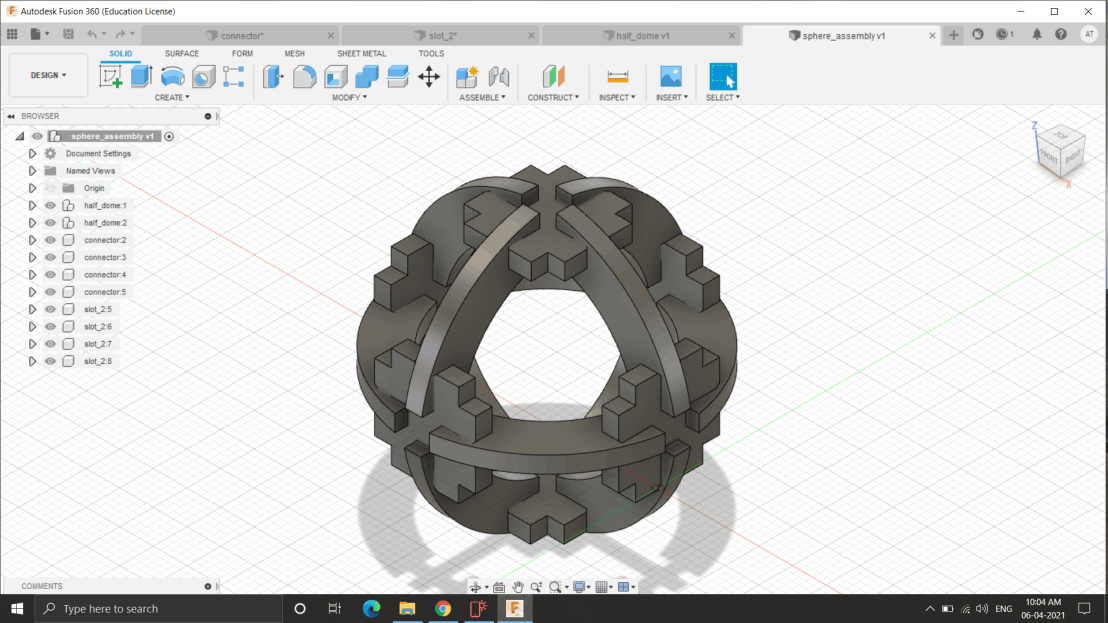

Laser Cutting

Dumble using construction kit

Sphere using construction kit

My Friend trying hard to workout using the dumble.

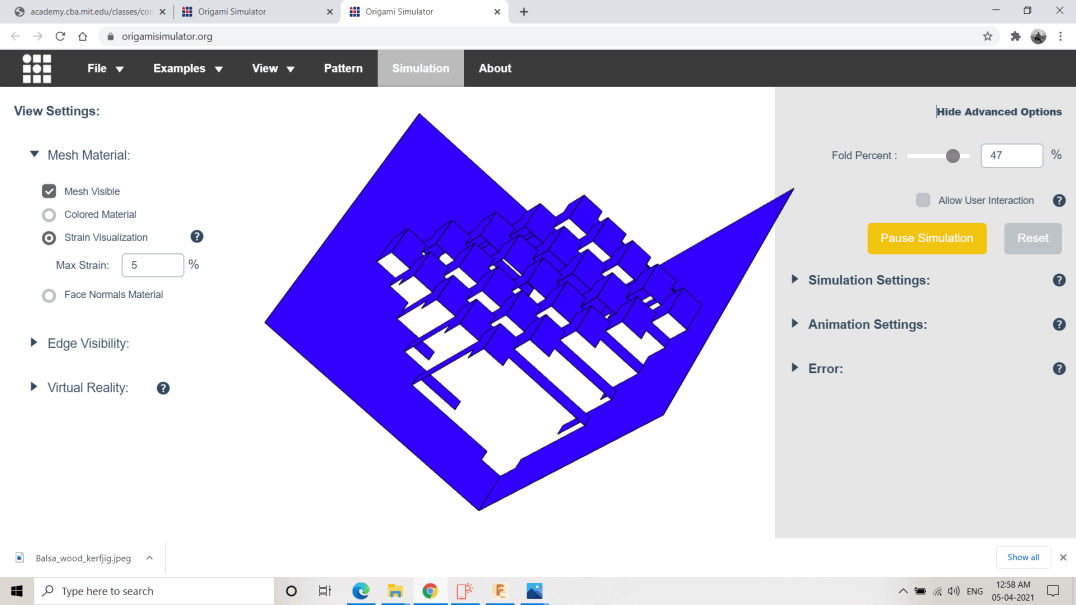

What is kerf Bending?

Kerf bending is a method where many slots are cut into wood to create beams and are capable of bending. Where these cuts turn the solid piece of wood into a series of interconnected beams, and these beams bend by torsion. They are also called as living hinges.

Curved Laser Bent Wood

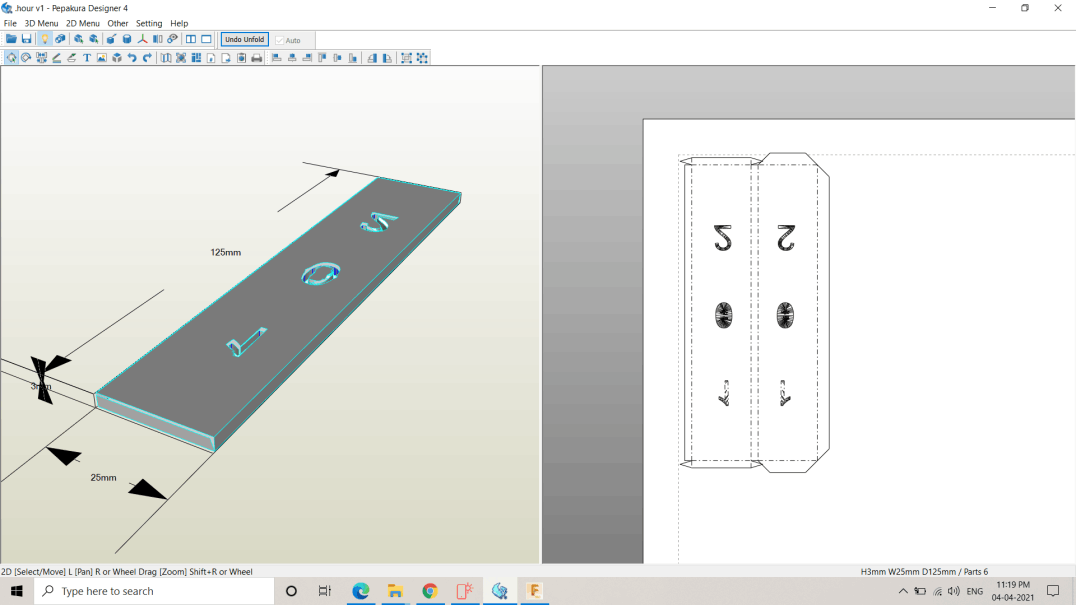

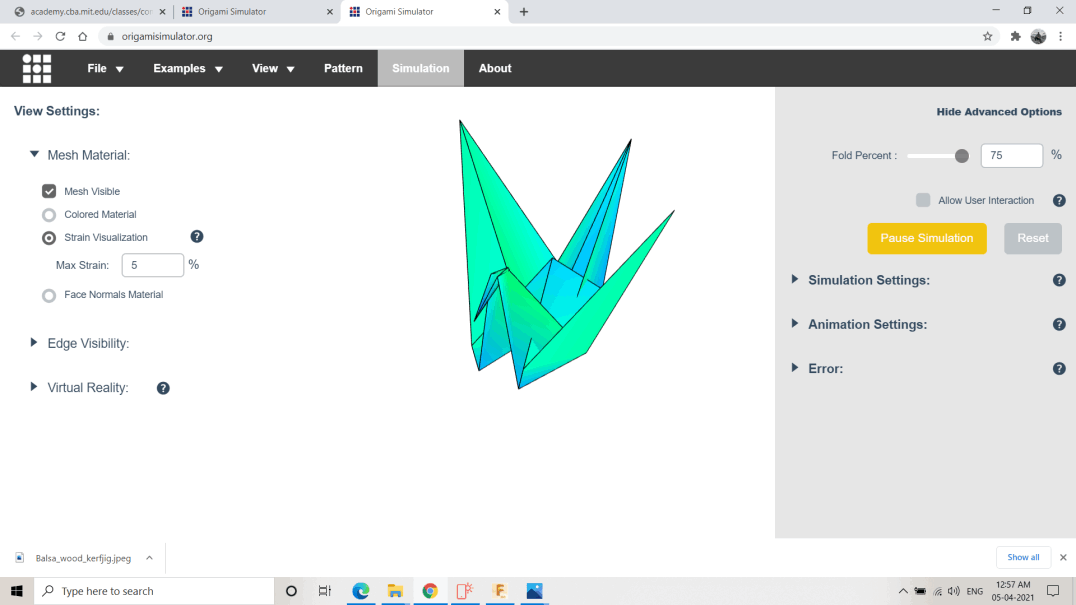

Best part is it can accept .Stl files and auto convert.

The software is more capable but due to limited time.

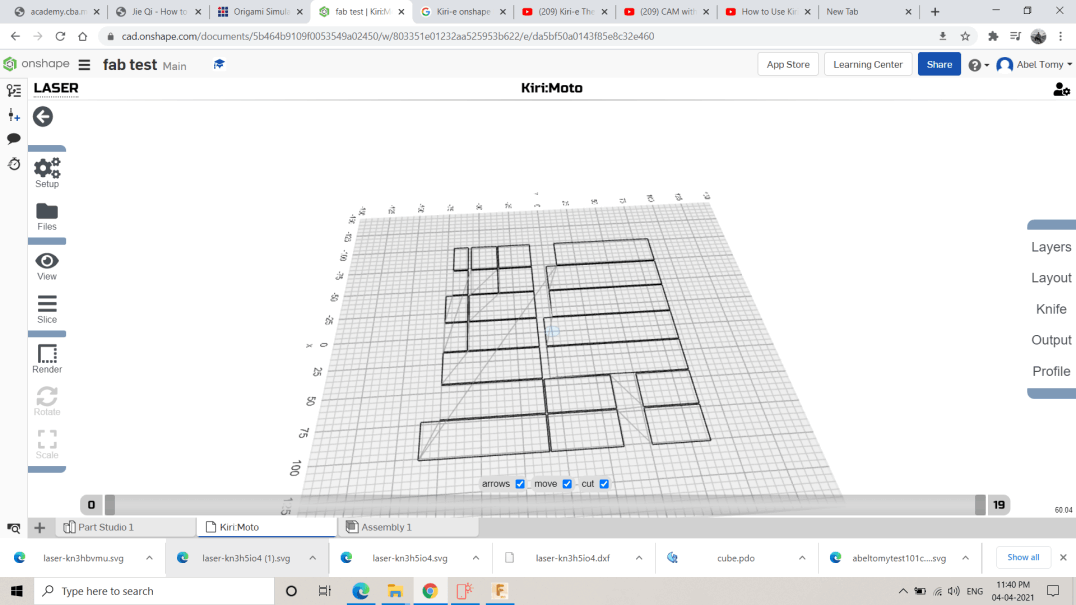

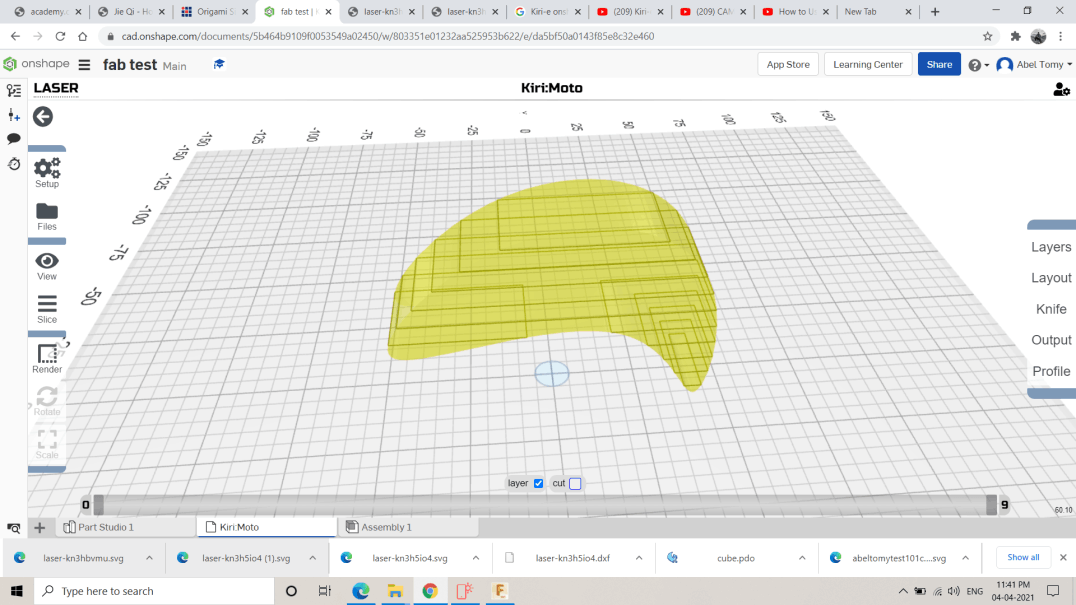

Prerequisite-Model in Onshape

1. Setup Menu Selects A Device And Mode(Select Laser,it can also do FDM,CAM,SLA etc.)

2.Open Files Or Import Parts To The Workspace.

3.Use The Right Side Profile Menus To Customize Slicing Parameters(Layer Height).

4.E Slice Objects To See The Effect Of The Parameters

5.Export Converts Paths To GCode or SVG Files.

Exporting to SVG.

Slicing by inputting layer height.

Import image and tamper with settings and export as .Svg

Designed with Mobirise theme